Hebei Evo-Tech Rigid Chain Technology Empowers Heavy-Duty AGVs—Setting a New Benchmark for Heavy Industrial Handling

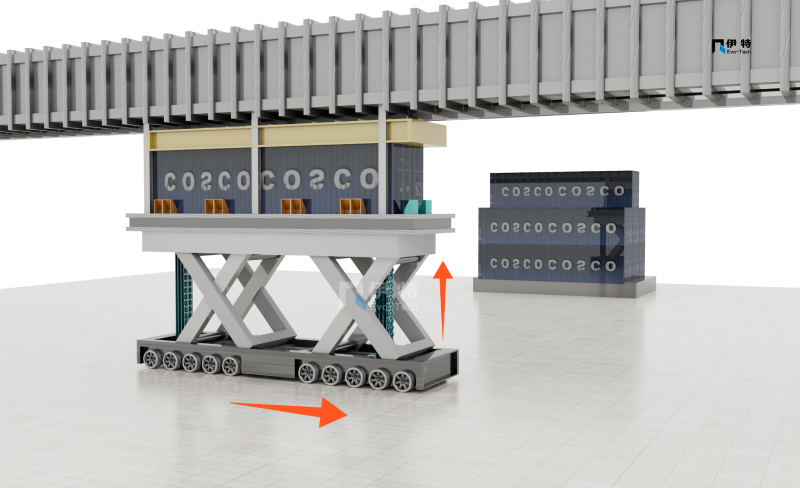

In heavy industrial settings such as steel metallurgy and port terminals, the handling of materials weighing tens of tons has long been a persistent challenge. Traditional manual operations suffer from low efficiency and high safety risks, while conventional AGVs struggle to meet the demands of heavy-load and high-intensity tasks. Hebei Evo-Tech's innovative rigid chain drive technology equips heavy-duty AGVs with "steel-like robustness," emerging as a game-changing solution for intelligent upgrades in heavy industries.

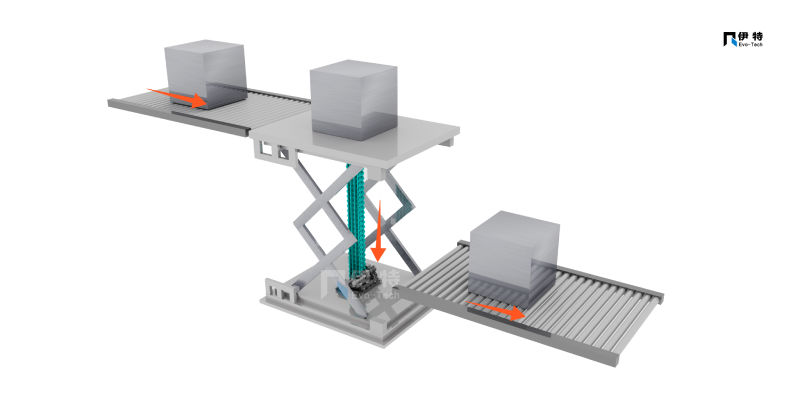

Rigid Chain Drive Empowers AGVs to Effortlessly Tackle Heavy-Load Lifting Challenges

1.High Efficiency and Cost-Effectiveness

In industrial handling, rigid chains enable AGVs to lift heavy loads, transforming "manual carrying" into "precision robotic lifting," significantly improving efficiency and reducing labor strain.

2. Precision and Stability for Complex Scenarios

Rigid chains achieve millimeter-level repeat positioning accuracy with zero settling over time. For instance, in automotive production lines, AGVs must precisely lift car bodies to welding stations. Hydraulic systems may cause minor deviations due to pressure fluctuations, whereas rigid chains ensure millimeter-level alignment, minimizing errors.

3. Low Maintenance, Eco-Friendly, and Energy-Efficient

Rigid chains outperform hydraulic systems in environmental performance due to their simple structure, high reliability, and easy maintenance. They eliminate oil leakage risks inherent in hydraulic systems, thereby enhancing safety.

Extended Application Scenarios

The technology also allows customization of lifting speed and minimum height, making it suitable for automated warehouses and port logistics. For example, AGVs in warehouses require rapid height adjustments to align with shelves, where the high-speed response of rigid chains boosts loading efficiency.

In summary, rigid chain drives combine precision, durability, and cost-effectiveness in heavy-load lifting tasks through structural innovation, establishing themselves as a pivotal technology for smart manufacturing advancement.